"whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU" (whiskey-business)

"whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU" (whiskey-business)

04/16/2015 at 17:24 • Filed to: None

1

1

13

13

"whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU" (whiskey-business)

"whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU" (whiskey-business)

04/16/2015 at 17:24 • Filed to: None |  1 1

|  13 13 |

I have an idea. Would it be plausible to take this

(RWD tube framed car)

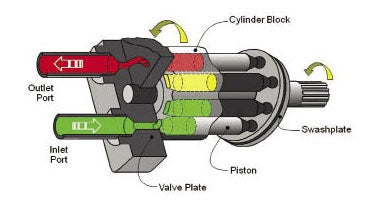

and add this

(Hydraulic drive pump)

!!! UNKNOWN CONTENT TYPE !!!

and 4 of these

(Hydraulic wheel motors)

To make a lightweight, high power, all wheel drive monster on the cheap?

!!! UNKNOWN CONTENT TYPE !!!

I mean in theory, it all works out. Remove powertrain up to the transmission output shaft, attach pump, and run high-pressure hydraulic lines to the four wheel motors. Assuming everything is sized correctly, these hydraulic motors would put out a huge amount of torque to all four wheels, allow for independent suspension at all 4 corners, and have relatively few downsides. Any engineers want to chime in?

Herr Quattro - Has a 4-Motion

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Herr Quattro - Has a 4-Motion

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

04/16/2015 at 17:28 |

|

No.

Why?

We as a species are unprepared for this amount of awesome.

Tohru

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Tohru

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

04/16/2015 at 17:29 |

|

1. The rule about hydraulic systems is that if it is not leaking hydraulic fluid, you are out of fluid.

2. Complicate and add weight.

RamblinRover Luxury-Yacht

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

RamblinRover Luxury-Yacht

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

04/16/2015 at 17:33 |

|

Independent suspension with huge unsprung weight, huge driveline losses, poor behavior characteristics at high speed... 4x hydrostatic drive isn't much better than 1x primary hydrostatic drive, and about the only thing primary hydrostatic drive is good for is a tractor. See also Tohru: leaks, and all this is as heavy as hell. Huge starting torque is one thing, but these motors aren't really made for rapid acceleration past that point - it takes a lot of work to get large quantities of hydraulic fluid in lines moving fast. You made something that can chirp the tires and then crawls up to speed - huzzah.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Tohru

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Tohru

04/16/2015 at 17:38 |

|

Hmm . . . if properly designed and build, would it really be that leaky? And I understand I'm adding complexity, but this is all reversible and just for fun.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> RamblinRover Luxury-Yacht

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> RamblinRover Luxury-Yacht

04/16/2015 at 17:39 |

|

Interesting. Maybe if it was attached to the input of a normal rear end?

RamblinRover Luxury-Yacht

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

RamblinRover Luxury-Yacht

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

04/16/2015 at 17:43 |

|

...then it's just a normal tractor, not a goofy tractor.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> RamblinRover Luxury-Yacht

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> RamblinRover Luxury-Yacht

04/16/2015 at 17:44 |

|

I guess so. I was under the impression I was onto something. Are hydraulic motors inherently high torque only at low rpm?

RamblinRover Luxury-Yacht

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

RamblinRover Luxury-Yacht

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

04/16/2015 at 17:48 |

|

High torque and high usable torque for acceleration are two wholly different things. If a motor can turn over with arm-breaking torque but can only accelerate itself very gradually, then you've just got a locomotive. Everybody knows a locomotive is powerful, but rapidly accelerating? Never. If the motor actually gets up to a high speed, then sure, it'll continue to maintain high torque when it's there, but getting up to that speed is... hard. It's like having a crushingly huge flywheel on your driveline - beyond a certain rate of hurrying up, all the huge torque of the system is being eaten trying to accelerate the system, not the vehicle. Dynamic loads are a bitch and a half.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> RamblinRover Luxury-Yacht

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> RamblinRover Luxury-Yacht

04/16/2015 at 17:56 |

|

I didn't think of the fluid in the system as a huge flywheel. . . It makes sense now that you say it like that.

RamblinRover Luxury-Yacht

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

RamblinRover Luxury-Yacht

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

04/16/2015 at 17:59 |

|

Now count in that fluid shear resistance is proportional to velocity, and the faster the fluid is going and the faster it attempts to change speed the more that has an effect just through friction in the system, and it's even worse.It's like a flywheel which is also spinning in a pit of mud.

Tohru

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Tohru

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

04/16/2015 at 18:11 |

|

Hydraulic systems always leak. Always.

JustBob

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

JustBob

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

04/16/2015 at 19:17 |

|

Mark

> Herr Quattro - Has a 4-Motion

Mark

> Herr Quattro - Has a 4-Motion

08/26/2016 at 01:56 |

|

I know the guy in the picture. Raced with him for years. Nice guy. His name was Bill Hostetler